CREO Course by ANH

See Page Topics

Overview

Creo is a family or suite of design Software developed by Parametric Technology Corporation (PTC) in year 2011.

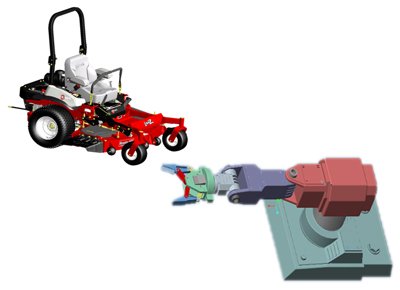

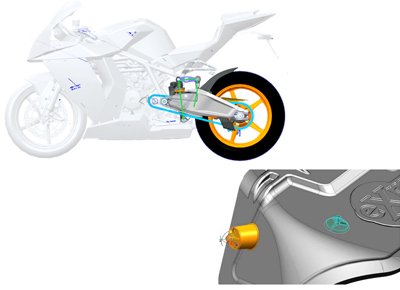

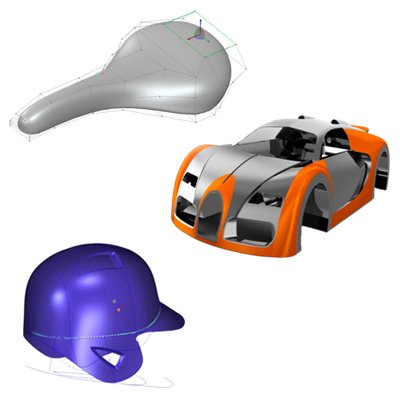

Creo is a Computer Aided Design tool used to create, analyze, view, and share designs downstream using 2D CAD, 3D CAD, parametric and direct modeling capabilities. Using Creo one can perform 3D Design, Industrial Design, Concept Design, Routed Systems Design, and Simulation.

Applications

Creo is used widely across Aerospace, Automotive, Alternative Energy, Construction, Consumer Product, Engineering services, Industrial Machinery & Heavy Equipment, Manufacturing, Mold Tool & Die, Oil & Gas, Packaging Industries, Process & Plants, and Education.

Course Highlights

Why ANH‘s CREO Course?

What Sets Us Apart

– Industry expertise:AutoCAD course

Our trainers are experienced engineers with years of industry experience, ensuring you learn from those who have been in your shoes.

– Practical focus:AutoCAD course

Our training is focused on practical applications, not just theory, so you can apply your skills immediately.

– Access to latest technology:AutoCAD course

As an industrial engineering services company, we have access to the latest software and technology, which we incorporate into our training.

– Real-world projects:AutoCAD course

You’ll work on real-world projects, not just simulations, to gain valuable experience and build a portfolio of work.

– Mentorship:AutoCAD course

Our trainers will guide and mentor you throughout the course, providing feedback and support to help you improve.

Creo course: Foundation

Part Modeling

Advanced Part Modeling

Assembly Design

Advanced Assembly Design

Flexible Modeling

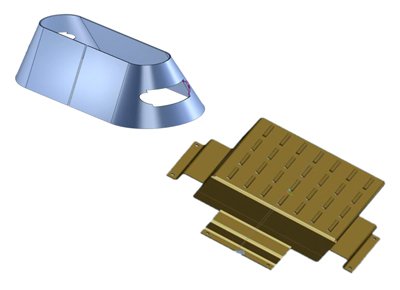

Sheetmetal Design

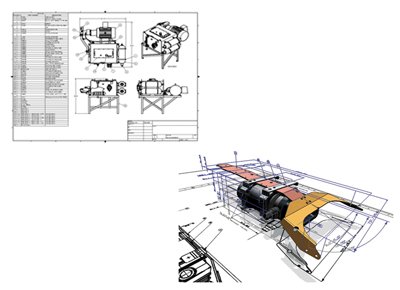

Drawing

Creo course: Advanced

Creo Advance- CAD Module

Creo-Analyst – CAE Module

Creo production- CAM Module

Duration

45 Hours Theory

45 Hours Practical

20 Hours Project work

Duration

30 Hours Theory

30 Hours Practical

20 Hours Project work

Technical Features

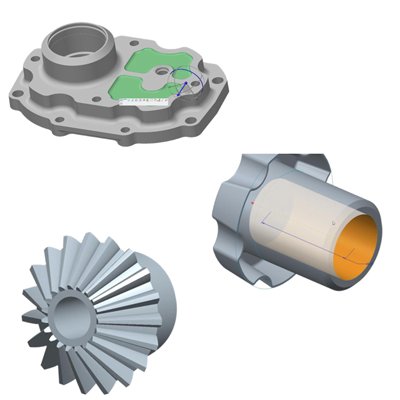

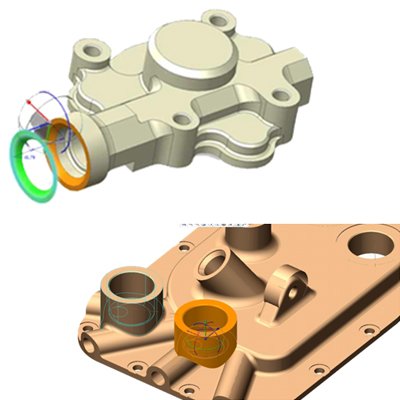

Creates Precise and Accurate 3D Complex Geometry based on the 2D Sketches

Parametric and Parent-Child Relation allows designers to modify design at any time

Feature based Modeling Software

Import and Export CAD Models for other CAD Tools

Creates 3D Models based on the Multiple Geometry

Capture the Details of the Model like Mass Properties

Manages the Cross- Section, Orientation an Representation of Models

Dynamically Editing of the Geometry

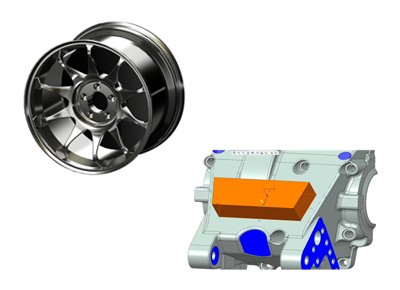

Smarter and Faster Assembly Modeling

Performance

Create Simplified representation on-the-fly

Leverage the real-time Interference detection

Top Down Design Approach

Use Fit, Form and Function Approach to Create Assembly Quickly and Accurately

Plan and Manage Large Assembly

Make Changes with confidence, knowing that modifications are automatically propagate from the design to manufacturing information

Quickly and efficiently customize product variants according to a customer’s unique requirements

Accelerate Detailed Design by Editing Parametric Design faster and Easier

Easy Selection of Geometry, Including Surfaces and Shapes

Simultaneously changes multiple Entities

Work Faster with imported data like neutral file as IGES, STEP & CAD Software like SolidWorks, Inventor etc.

Create Sheetmetal Components faster and efficiently

Automatically Generates flat patterns from 3D Geometry

Use Varieties of Bend Allowance Calculations to Create Flat pattern of the designs

Create 2D and 3D Drawings according to International standards, including ASME, ISO and JIS Standard

Create an Associative Bill of material and Associate Balloon Notes Automatically

Automate the Creation of Drawings with Templates

Easy to Convert Drawings in PDF, Drawings and 3D PDF Formats

Design Precise curves and surfaces to achieve highly-engineering manufacturable products

Confidentially explore design variants by making fully associative changes at any time

Intuitive user interface provides direct surface editing capabilities, real-time feedback and allows rapid and extreme product design.

Create products that look better, sell better and get to the market faster

High-Quality, Parameterized surfaces can be immediately reused in a 3D detailed design process

Multilevel sub divisional modeling for more control over the surface, enabling finer detailing without altering the existing shape.

Build free form geometry at any point in the design, using as many as or as few constraints as desire For maximum design flexibility.

Easy to learn and use, Intuitive and direct modeling approach allows new or infrequent users to get up to speed quickly and create and edit 3D

Designs

Faster and More flexible part modeling and assembly modeling increases individual efficiency and Productivity.

Easily Accommodate late- Stage Changes to your engineering design faster and with less frustration with this fast and easy approach

Work More efficiently in multi CAD environment by easily incorporating and editing data from other CAD system.

Increase process efficiency

UI is based on weld symbols and terminology

Libraries for weld process and rod material

Extract valuable information from the model, such as mass properties, clearances, interferences, and cost data.

Determine amount of rod material required

Document welds using Industry standard Symbols

Define Joining requirements

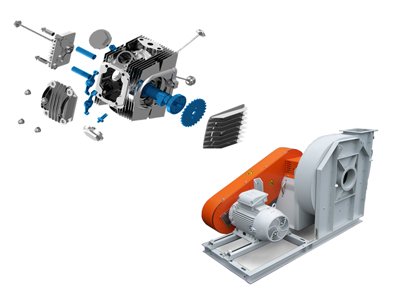

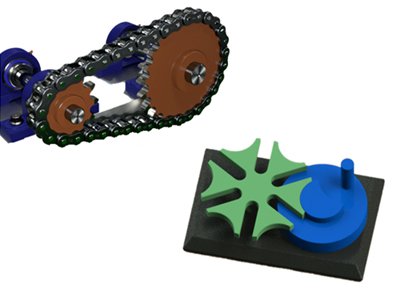

Ability to convert between assembly constraints and mechanism joints automatically

Easily control positions, speeds and accelerations of components and subassemblies

Create space claims provide collision warning

Simply reuse your model with options to include mechanism simulations

Visualize assembly/ disassembly sequences

Any and all design changes are immediately shown

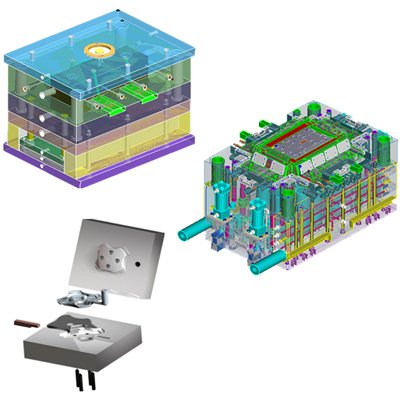

Automated functions and special GUI’s for 17 moldbase and component suppliers

Includes screws, ejector pins, sliders, lifters, cooling fittings, etc

Mold opening with interference checking of moldbase and components

All necessary clearance holes, threads, counter bores, etc. are automatically added to plates

Custom Components can be created, saved and reused

Standard and nonstandard mold components are marked

Ability to take your customer parts through the complete process

Supplier catalogs include : DME, DMS, EOC, FUTABA (Misumi) HASCO, KLA, MEUSBURGER, PEDROTTI, RABOURDIN, STRACK, PROGRESSIVE, NATIONAL,PCS,LKM

and others

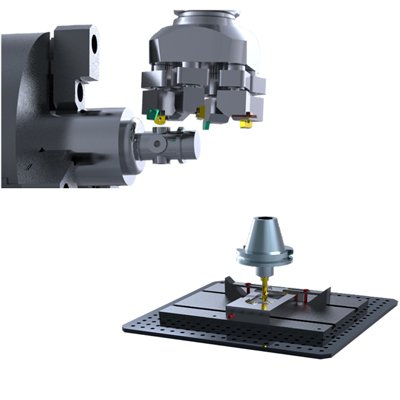

Multi-surface 3-aixs milling with support for high –speed machining 4-axis and 5-axis positioning NC-program creation, process documentation, post-processing and tool path verification/simulation Improves

product quality and Mfg consistency by generating tool paths directly on solid models Part of an integral CAD/CAM solution – no data translation required Reduces time –to market via associative tool path

updates to design changes

CREO Production Machining Extension

Includes all the capabilities of Creo Prismatic and Multi-Surface milling Extension Supports CNC Mills, 2 –axis and 4- axis CNC lathes, and 2 –axis and 4 – axis CNC wire EDM machines Provides low –level NC

sequence editing allowing precise toolpath control and optimization

Case Studies

Coming Soon

Let’s start working together! Get in touch with us!

If you would like to work with us or just want to get in touch, we’d love to hear from you!